FOOD EQUIPMENT

Vacuum Cooler

< CM-100〜300GB / GD >

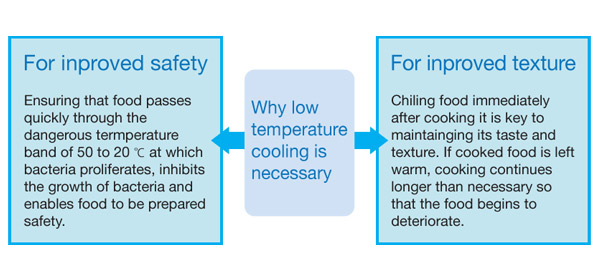

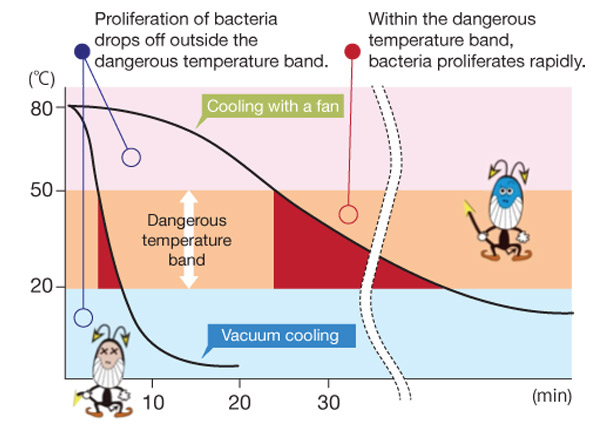

Safety is of crucial importance when offering food services. However in recent years, there have been many cases of food poisoning, and greater hygiene control is called for at food processing sites. The main hazard in food production is harmful microorganisms. To ensure safety, it is essential to prevent contamination and proliferation of microoraganisms. But because they are everywhere in the natural environment, achieving zero contamination can be difficult. However, there are methods for preventing the proliferation of harmful microorganisms. Temperature control is one such method, and vacuum cooling is seen as the most effective method for achieving the ideal temperature control. Cooling technology is an essential element of hygiene control, and now MIRA is offering a solution to the needs of the food processing industry, in pursuit of a higher level of safety.

(What is vacuum cooling?)

With vacuum cooling, the air is drawn out of the cooling cessel and the food is chiled quickly using the heat of vaporization.

(Effective in preventing food poisoning)

- Cooling is possible in a much shorter time than with a cooling fan.

- The cooked food is chiled uniformly, leaving no heat at the core.

- After cooling, air is supplied to the vessel via a sterilizing filter, ensuring hygiene.

The PID cooling control effect

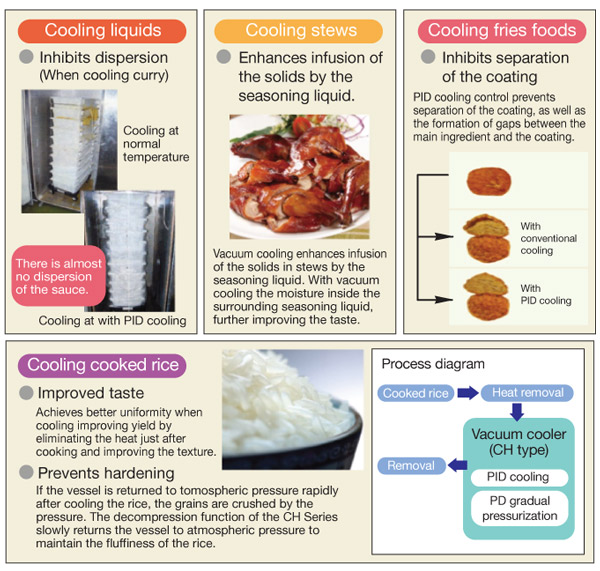

| Cooling liquids | Suppresses dispersion |

|---|---|

| Cooling stews | Enhances infusion of the solids by the seasoning liquid Keeping of juicy feeling |

| Cooling fried foods | Inhibits separation of the coating |

| Cooling cooked rice | Fluffy |

| Reduces temperature irregularities between different foodstuffs |

*Some cooked foods and containers are unsuitable for vacuum cooling.

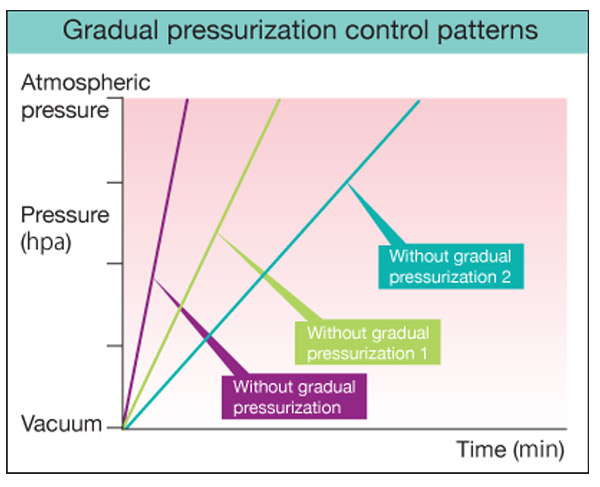

Select from 5 PID cooling curves

- Conventional vacuum coolers the agree of vacuum in the cooling vessel is detected, and the food is cooled with automatic control according to the present cooling curve

- Choice is possible from 5 cooling patterns depending on the kind of food

PID control is alsoused in the gradual pressurization process, acheving smooth operation

Automatic adjustment of the valve has replaced the earlier gradual valve on/off control, enabling uniform release of the vacuum.